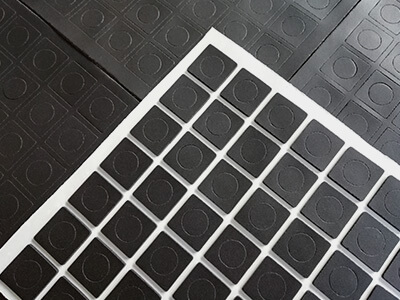

Foam die cutting is a very basic but also popular foam fabrication technique that easily allows the same shape to be generated uniformly in various foam materials. Steel rule die cutting is one of the most frequently used die-cutting forms. At first, we need to develop a precise steel rule die according to custom specification and requirements. A sheet of steel will be bent and formed into an exact custom shape. After the steel rule die finished correctly, we then place it onto our high speed die-cutting machinery. The foam material is then pressed onto the blade of the die, cutting through the material to generate the finished foam products. Die cutting is a quite handy and efficient way for regular foam fabrication.