The Most Popular Foam Products Used in Construction Industry

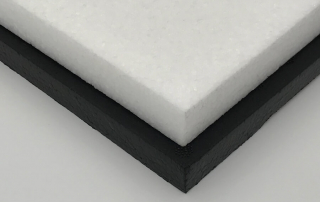

Foam material are available in closed cell and open cell structure, and they are also available in a broad range of densities and firmness, which can help foam perform well on shock absorption, sound dampening, water resistance, and heat insulation. With all versatile properties, foam products are naturally