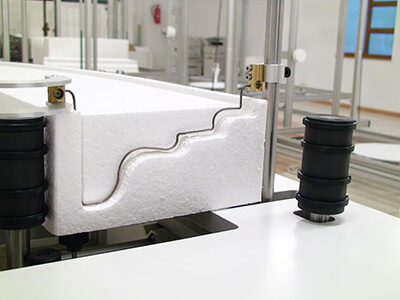

FOAMTECH has hot wire foam cutting capacity for custom foam fabrication. Our hot wire cutting technique is an innovative technology that uses an electrically charged metal wire to cut through many different types of foam including EVA foam and cross linked polyethylene foam. It is CNC controlled and able to cut custom precision shapes from different foam material with diverse density. Because the wire is controlled through computerized programming, custom shapes can be cut without expensive tooling cost. Shape dimensions can be directly imported from customer’s CAD drawing files. This allows us to cut a range of production volumes accurately and efficiently while remaining production cost competitive. Also our hot wire cutting technique is especially suitable for projects requiring to cut cavities and contours in foam. Please contact us to find your custom tailored foam fabrication solutions.