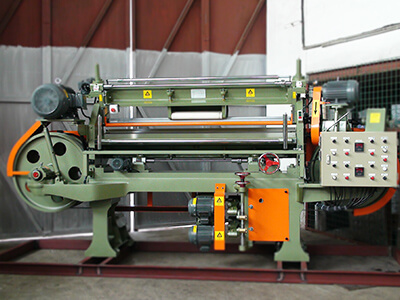

Foam Skiving & Splitting

Our foam skiving & splitting machines are highly efficient and accurate to shave raw material in sheet to any required thickness. The skiving machinery are versatile to all sorts of foam material. Splitting & skiving is often a transition phase for other process of foam fabrication. To show you how it works, usually the foam sheet comes with a large thickness so we need to split them to wanted thickness. Inside the skiving machine, there is a horizontal steel blade which is used to shave the foam sheet into two pieces. After our technicians adjust the required thickness, we then put the foam sheet horizontally crossing through the skiving machinery. Finally we can have the foam sheet or block in wanted thickness. The foam sheet or block will be used in other foam fabrication process, such as die cutting and CNC contour cutting etc.. The splitting & skiving technique is quite useful to produce wanted thickness foam material. You could also get a naturally clear and smooth surface of foam material with tight tolerance after skiving.

Typical industry and foam product:

-

Foam seals and gaskets

-

Foam packaging

-

Marine products

-

Foam sheet and block