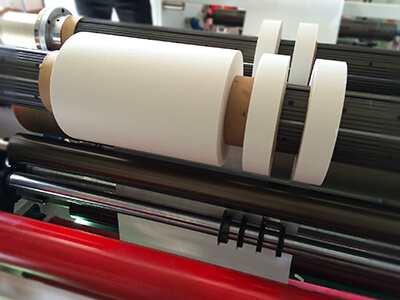

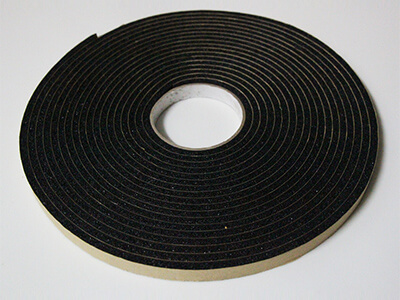

Using our state of art automatic foam slitting machines, FOAMTECH offers a variety of slitting methods to slit plenty of foam material with or without adhesive to achieve custom widths. The mainly slitting techniques are lathe slitting and rewind slitting. Lathe slitting which also refers to as baloney, lever and single-knife slitting is an efficient and economical way for slitting foam material. Before the lathe slitting process, our factory staff need to make foam material in roll usually, Also we use our lathe slitter to cut the foam sheet into strips. Then we load the foam roll on a horizontal steel mandrel and spin the roll at a high speed by operating the lathe slitter. In the meantime, the spinning foam roll will be cut through by a circular blade to the specified custom width. Spinning speed can be controlled numerically by our slitter. For the rewind slitting, this technology provides tight tolerance and more accurate slitting capability and the flexibility to vary the width and length of foam material.