When you try to find packaging for your new product, you should have known this process can be real time-consuming. The packaging for a product especially targeted for end-user market can never only include paper packaging for product. For most cases, your fragile products might need protective foam packaging insert for its safe shipping, presentation and storage.

Here we are going to illustrate some common foam packaging types, so it can be much instructive for you to choose the right foam packaging solution for new products. The most frequently used foam material for protective packaging include EVA foam, EPE foam, PU foam, Cross-linked PE foam ( XPE foam & IXPE foam), EPS foam ect.. Also some of those foam materials can be possessed of enhanced properties by utilizing different fabrication techniques.

When you are in face of all these foam materials for a packaging solution, it could be evidently bewildering. Let's go forward and learn more about them.

EVA Foam Packaging & EVA Foam Insert

Remember! When you are considering a foam packaging design, EVA foam could be your No.1 option!

EVA foam material is offered in various densities and colors, and this makes it a very common and popular foam material for custom foam packaging insert. For heavy products, we can use high density EVA foam sheets to fabricate custom foam inserts. High density EVA foam insert can provide better tensile strength and protective supporting for heavy goods. On the other hand, medium density and low-density EVA foam can be much suitable for products with light weight.

EVA Foam Insert - Feature & Benefit

EVA foam sheets are available in multiple colors and can be manufactured in even any colors within PMS color chart.

- Moisture, Water, Heat and Oil resistance

EVA foam are typically closed cell foam material which is good at resistance of moisture, water, heat, oil and other fluid. Those properties are vital for keeping and transporting your precious goods. By using EVA foam material, you will not have to worry kept products being affected by moisture and water. Also You could always find EVA foam used in many foam packaging products like EVA foam insert box, Jewelry foam insert, gift box foam insert, foam insert for tool box and so on.

EVA foam are typically closed cell foam material which is good at resistance of moisture, water, heat, oil and other fluid. Those properties are vital for keeping and transporting your precious goods. By using EVA foam material, you will not have to worry kept products being affected by moisture and water. Also You could always find EVA foam used in many foam packaging products like EVA foam insert box, Jewelry foam insert, gift box foam insert, foam insert for tool box and so on.

- Consistent Cushioning Protection

As mentioned before, EVA foam is available in a wide range of densities from 33 kg/m³ to around 280 kg/m³. They are suitable for packing various weight of products by using different density foam. EVA foam insert is generally flexible and cushioning compared with hard and solid plastic material. EVA foam cut out packaging can provide excellent cushion protection for products kept within foam inserts.

As mentioned before, EVA foam is available in a wide range of densities from 33 kg/m³ to around 280 kg/m³. They are suitable for packing various weight of products by using different density foam. EVA foam insert is generally flexible and cushioning compared with hard and solid plastic material. EVA foam cut out packaging can provide excellent cushion protection for products kept within foam inserts.

- Easily Work With Various Foam Fabrication Processes

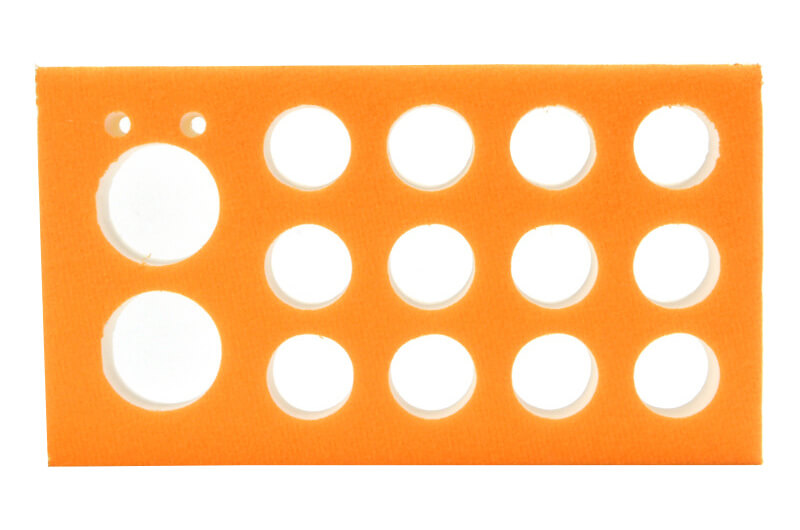

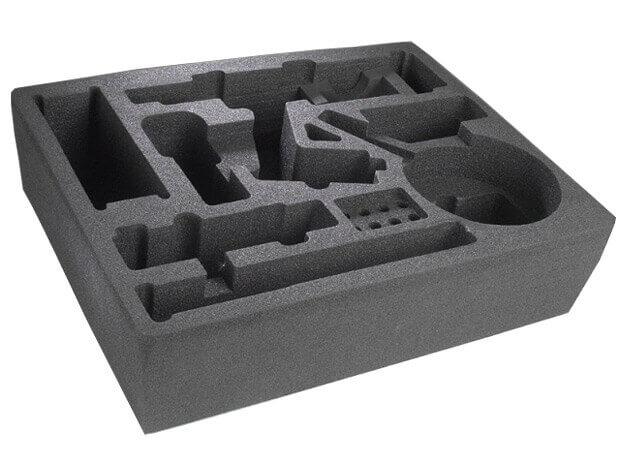

EVA foam can be fabricated by various fabrication techniques including custom steel die-cutting, compression punching, PSA lamination, CNC contouring cutting, hot wire cutting, foam thermoforming and so on. All these techniques can be quite helpful to achieve custom required foam packaging solutions such as foam pick and pluck, foam insert with holes and EVA foam cut out.

EVA foam can be fabricated by various fabrication techniques including custom steel die-cutting, compression punching, PSA lamination, CNC contouring cutting, hot wire cutting, foam thermoforming and so on. All these techniques can be quite helpful to achieve custom required foam packaging solutions such as foam pick and pluck, foam insert with holes and EVA foam cut out.

- Easily Work With Custom Printing

When you consider having custom printed foam packaging, EVA foam could be a right choice. Compared with cross-linked polyethylene foam or PU foam, EVA foam has a smooth surface which makes it quite suitable for custom printing requirements.

When you consider having custom printed foam packaging, EVA foam could be a right choice. Compared with cross-linked polyethylene foam or PU foam, EVA foam has a smooth surface which makes it quite suitable for custom printing requirements.

- Available In Various Colors For Better Product Presentation

EVA foam materials are molded foam buns and can be provided in a wide range of colors. When you are considering releasing a new product, colorful EVA foam insert can help provide impressive and professional product presentation. They can be made for a foam insert box in 2 or more different colors and could be more eye-catching.

EVA foam materials are molded foam buns and can be provided in a wide range of colors. When you are considering releasing a new product, colorful EVA foam insert can help provide impressive and professional product presentation. They can be made for a foam insert box in 2 or more different colors and could be more eye-catching.

- Laminated Velvet Available For Luxury Foam Insert

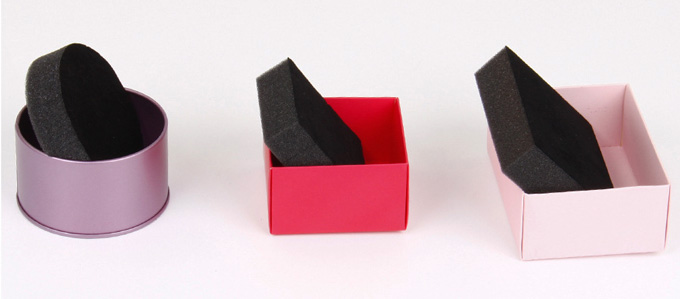

For some particular items like luxury goods, sometimes they indeed need foam cushioning insert for protection. They also have strict aesthetics requirements for product presentation. EVA foam packaging can be designed with soft and touchable velvet or felt. Velvet foam insert and foam insert tray are perfect to use for gift box, jewelry box, watch box and so on.

For some particular items like luxury goods, sometimes they indeed need foam cushioning insert for protection. They also have strict aesthetics requirements for product presentation. EVA foam packaging can be designed with soft and touchable velvet or felt. Velvet foam insert and foam insert tray are perfect to use for gift box, jewelry box, watch box and so on.

EVA Foam Insert - Difference From Other Foam Packaging

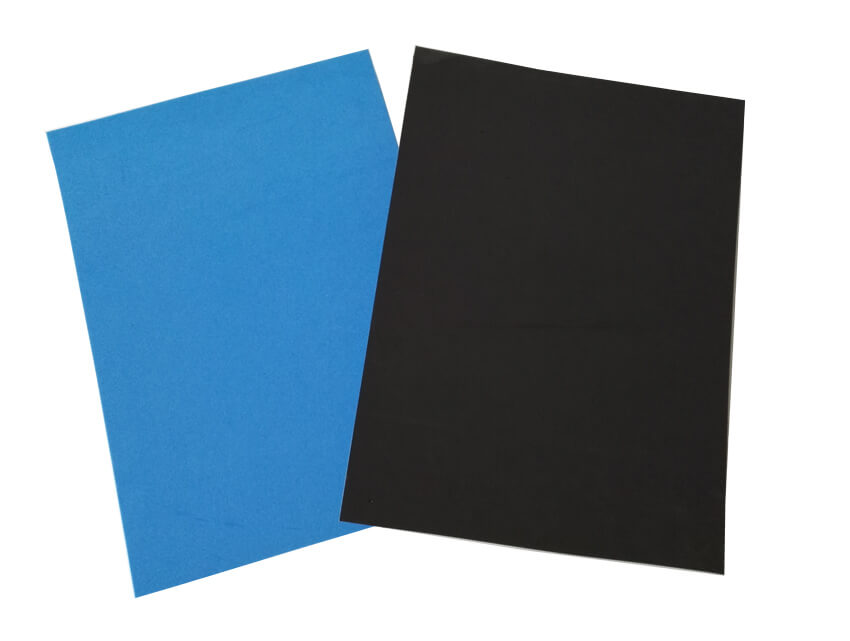

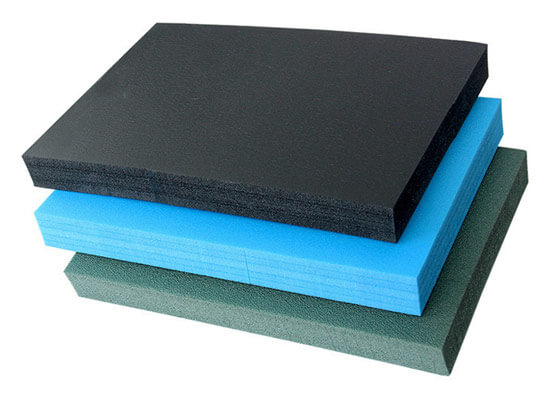

The EVA foam has smooth surface and is available in various colors including white, black, blue, red, gray, yellow etc.. They are also offered in various densities normally from 33 kg/m³ to around 280 kg/m³ in different firmness from 15 shore C to 80 shore C. They are suitable for most of general purpose foam packaging including foam case insert, EVA velvet foam insert, EVA tool box foam insert.

The EVA foam has smooth surface and is available in various colors including white, black, blue, red, gray, yellow etc.. They are also offered in various densities normally from 33 kg/m³ to around 280 kg/m³ in different firmness from 15 shore C to 80 shore C. They are suitable for most of general purpose foam packaging including foam case insert, EVA velvet foam insert, EVA tool box foam insert.

EPE Foam Insert - Low Cost Foam Packaging Solution

Expanded Polyethylene Foam also know EPE foam has been a very economical foam packaging material. Besides being made as EPE foam packaging, they are also working as foam packing sheet for cushioning protection. Considering this, they are the most basic foam packaging products. You could find EPE foam in many packaging applications. White color is the standard color for EPE foam sheet that are frequently used as foam packing material. They could also be in black and pink color. Also you could note that pink EPE foam always has anti-static property. The pink color can make them stand out from standard white or black EPE foam.

You could find EPE foam in many packaging applications. White color is the standard color for EPE foam sheet that are frequently used as foam packing material. They could also be in black and pink color. Also you could note that pink EPE foam always has anti-static property. The pink color can make them stand out from standard white or black EPE foam.

EPE Foam Insert - Feature & Benefit

- Stable Foam Density and Lightweight

EPE foam material has consistent foam density ranging from 23 kg/m³ to 28 kg/m³. They are lightweight and cushioning foam material. This can be a good advantage that EPE foam packaging can save the total weight of cargo for shipment.

EPE foam material has consistent foam density ranging from 23 kg/m³ to 28 kg/m³. They are lightweight and cushioning foam material. This can be a good advantage that EPE foam packaging can save the total weight of cargo for shipment.

- Moisture and Water Resistance

Expanded Polyethylene foam has closed cell foam structure and they are non cross-linked Polyethylene foam. You could find them for applications such as floor underlay, foam packing sheet. When EPE foam used for foam packaging, they can also perform well on moisture and water resistance.

- Shock Absorption and Heat Insulation

Compared with EVA foam, EPE foam packaging can not outperform on durability. But EPE foam insert can perform better on heat resistance than EVA foam. They can also offer good basic impact absorption performance. EPE foam cut out packaging can ensure lightweight products safely for shipment.

- Low Cost Foam Packaging Solution

EPE foam could be the most cost-effective custom foam packaging material. They are low cost material and can provide basic also workable cushioning protection for production. When your priority is not aesthetics for foam inserts, EPE foam cutout packaging might be a good choice.

EPE foam could be the most cost-effective custom foam packaging material. They are low cost material and can provide basic also workable cushioning protection for production. When your priority is not aesthetics for foam inserts, EPE foam cutout packaging might be a good choice.

EPE Foam Packaging – Difference From Other Foam Packaging

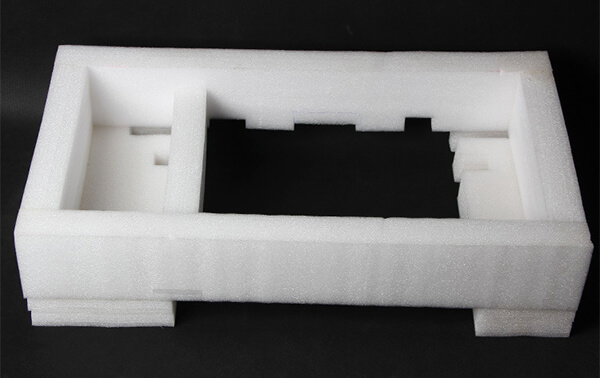

EPE foam packaging do not present a smooth surface like EVA foam or XLPE foam. They has an uneven and rough appearance. They are low cost foam packaging material with odor free. Also they have good performance on heat insulation and moisture resistance. EPE foam can be cut to size as customer requests which is popularly used for goods shipment and storage.

PU Foam Insert - Soft & Flexible Open Cell Foam Packaging

PU foam short for polyurethane foam is a kind of open cell foam material. Polyurethane foam are lightweight which is widely used in consumer goods such as bedding, furniture, carpet underlay and so on. Polyurethane foam has a wide range of densities. We usually use PU foam of density from 12 kg/m³ to 60 kg/m³ for PU foam packaging insert.

PU Foam Packaging - Feature & Benefit

- Lightweight and Soft

The PU foam material used for foam packaging is often lightweight, flexible and soft. It is open cell polyurethane foam. They could not compete with closed cell foam such as EVA foam and Polyethylene foam on water & moisture resistance. But they are good at resilience and that is why they can be the main material for sofa or furniture upholstery.

The PU foam material used for foam packaging is often lightweight, flexible and soft. It is open cell polyurethane foam. They could not compete with closed cell foam such as EVA foam and Polyethylene foam on water & moisture resistance. But they are good at resilience and that is why they can be the main material for sofa or furniture upholstery.

- Excellent Noise Reduction

As mentioned, PU foam used for cushion packaging is open cell material. They are excellent at noise reduction and can be custom convoluted as egg crate convoluted foam. They can be used for many acoustic required places such as recording studio and conference room etc..

As mentioned, PU foam used for cushion packaging is open cell material. They are excellent at noise reduction and can be custom convoluted as egg crate convoluted foam. They can be used for many acoustic required places such as recording studio and conference room etc..

- Flexibility, Resilience, Shock Absorbing

Like other foam materials, Polyurethane foam is also flexible and resilient. Foam case insert made by PU foam can be good at shock absorbing. Also PU foam is usually used for packing lightweight items in small gift boxes or cases.

Like other foam materials, Polyurethane foam is also flexible and resilient. Foam case insert made by PU foam can be good at shock absorbing. Also PU foam is usually used for packing lightweight items in small gift boxes or cases.

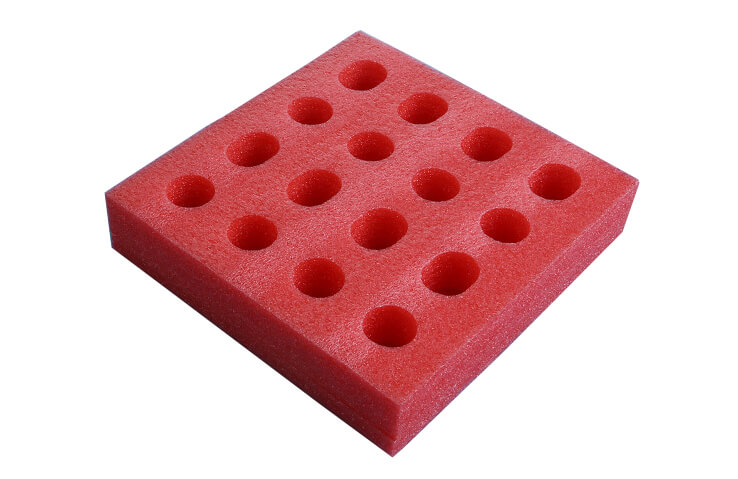

- Pick and Pluck Foam

Do not forget you could see PU foam mostly used for pick and pluck foam packaging which is a quick and convenient foam insert that can be available for DIY.

- Anti-static, fire retardant also various densities available

PU foam packaging can also be made with anti-static function by simply using anti-static PU foam material. They are quite suitable for packing special or precious electronics or metal instruments. Just like EVA foam, open cell Polyurethane foam is available in a wide range of density and can be a nice benefit for various custom applications.

PU Foam Packaging – Difference From Other Foam Packaging

PU foam has a unsmooth surface and you could find clear foam cell on all sides. They can be provided in a wide range of densities. PU foam inserts are resilient and flexible. They are good at sound reduction and shock absorption. But they are not resistant to moisture, water, oil and other fluid. Regarding production cost, they are usually more economical for foam packaging compared with PE foam and EVA foam.

Cross-linked Polyethylene Foam Packaging

Crosslinked Polyethylene foam is also a very popular choice for foam protective packaging. They are durable, strong and resilient which can be used for lots of industries including packaging, transportation, automotive, construction and so on. Polyethylene foam family includes EPE (Expanded Polyethylene) foam, XPE ( Cross-linked Polyethylene)foam and IXPE ( Irradiation Cross-linked Polyethylene ) foam also known as XLPE foam. EPE foam is non cross-linked foam material as we have already illustrated above, and the rest two are cross-linked foam.

Here we are introducing the rest of 2 kinds Polyethylene foam - XPE foam and XLPE foam which are higher quality PE foam. They can performs better on moisture resistance, heat insulation, vibration dampening and durability etc.. XPE foam and XLPE foam are both cross linked foam materials and can be provided in a wide range from 30 kg/m³ to 300 kg/m³. Polyethylene foam with density from 30 kg/m³ to 50 kg/m³ is mostly suitable for using as protective foam packaging. Compared with XPE foam, XLPE foam also short for IXPE foam can function better than XPE foam and can be used for medical applications and superior floor underlay.

Crosslinked PE Foam Insert - Feature & Benefit

- Premium Heat Insulation Performance

Work as custom foam packaging, PE foam can deliver excellent thermal insulation performance. You can find PE foam material used in many heat insulation required applications such as wood floor underlay, Polyethylene foam tapes, roofing construction and so on. Both crosslinked Polyethylene foam and irradiation cross linked Polyethylene (XLPE) foam can be excellent at heat insulation.

Work as custom foam packaging, PE foam can deliver excellent thermal insulation performance. You can find PE foam material used in many heat insulation required applications such as wood floor underlay, Polyethylene foam tapes, roofing construction and so on. Both crosslinked Polyethylene foam and irradiation cross linked Polyethylene (XLPE) foam can be excellent at heat insulation.

- Closed Cell Foam For Superior Moisture Resistance

Polyethylene foam is of closed cell foam structure which result in ultra low water absorption rate. PE foam packaging has the same properties and have superior performance on water & moisture resistance. Once your products placed in Polyethylene foam case insert, they can just be safe and sound for shipment and product presentation.

- Long-term Durability and Cushioning

Another excellent benefit for PE foam packaging is its long term durability. Both XPE foam and IXPE foam have premium properties at tensile strength, elongation and compression recovery abilities. PE foam have ideal resistance ability against moisture, oil and acid etc.. Custom polyethylene foam insert can protect your products with long term cushioning.

Another excellent benefit for PE foam packaging is its long term durability. Both XPE foam and IXPE foam have premium properties at tensile strength, elongation and compression recovery abilities. PE foam have ideal resistance ability against moisture, oil and acid etc.. Custom polyethylene foam insert can protect your products with long term cushioning.

- Ideal Shock Absorption

Just like other foam packaging, PE foam packaging are cushioning and flexible. Both cross-linked Polyethylene foam packaging and irradiation polyethylene foam insert can offer excellent vibration dampening for your products. They can effectively shelter precious goods from vibration and shock during transportation.

Just like other foam packaging, PE foam packaging are cushioning and flexible. Both cross-linked Polyethylene foam packaging and irradiation polyethylene foam insert can offer excellent vibration dampening for your products. They can effectively shelter precious goods from vibration and shock during transportation.

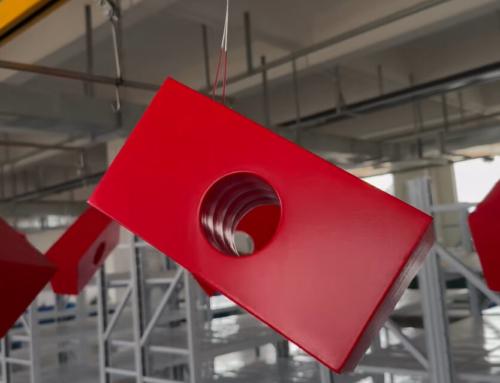

- Available in various colors, densities and easy to be custom fabricated

Same like EVA foam, Polyethylene foam can be offered by foam suppliers in various colors and densities. Black and white are the standard colors but other color such as red, green, blue also custom available. Regarding foam densities, both XPE foam and IXPE foam have a wide range of densities choice. They can tailor made to meet various customers' needs. Also PE foam can be easily working with all sort of foam fabrication processes including die-cutting, foam lamination, CNC contouring cutting, foam thermoforming and so on.

Crosslinked Polyethylene Foam Insert – Difference From Other Foam Packaging

Chemically Crosslinked PE foam material has an unsmooth outside surface. XLPE foam has a smoother surface and better technical properties compared with XPE foam. Both of them have excellent properties on moisture resistance, durability, resilience and heat insulation. They are excellent to be as foam packaging insert for industrial instruments and electronics. They can be available in a wide range of colors and densities from 30 kg/m³ to 300 kg/m³.

Chemically Crosslinked PE foam material has an unsmooth outside surface. XLPE foam has a smoother surface and better technical properties compared with XPE foam. Both of them have excellent properties on moisture resistance, durability, resilience and heat insulation. They are excellent to be as foam packaging insert for industrial instruments and electronics. They can be available in a wide range of colors and densities from 30 kg/m³ to 300 kg/m³.

Hope all above information can be informative and directive for you to choose your best foam packaging insert. For more question and idea, please contact us at info@www.foamtechchina.com.

Leave A Comment