EPP foam, short for expanded polypropylene foam, is a commonly used foam material that is used for a wide variety of application for insulation, protection, buoyancy and packaging ect.. Expanded polypropylene is made by molding methods and comes in sheets or various custom molded shapes and sizes.

What is EPP foam?

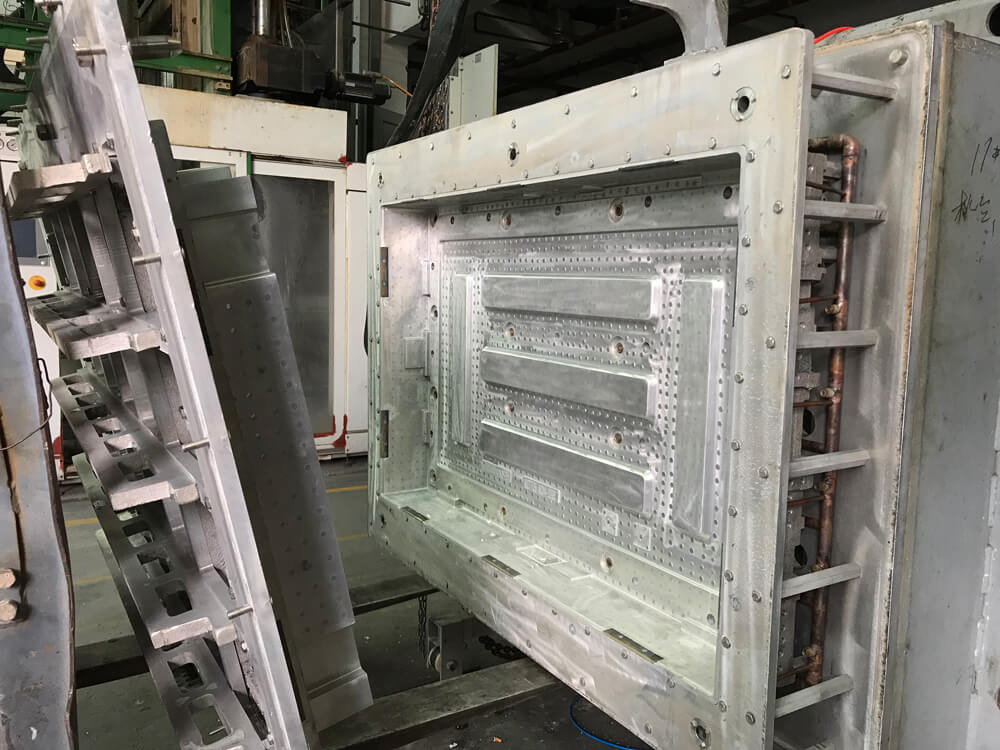

EPP is one kind of closed cell foam material that requires a very precise and complex manufacturing process, with highly specialized custom-made equipment operated by seasoned professionals. The material can be shaped into many different formats and sizes, and molds are often used, depending on the desired outcome. The material is porous, consisting of several polypropylene beads. They let air pass through the beads, helping with acoustic insulation and weight reduction as well. Because of its versatility, it is highly sought-after in various industries, from constructions, to shipping, and more. EPP is an excellent and cost-effective material for thermal insulation, and its high buoyancy makes it resistant to water and other chemicals. If this wasn’t enough, EPP foam is also quite sturdy, and it is completely sustainable, since it can be recycled.

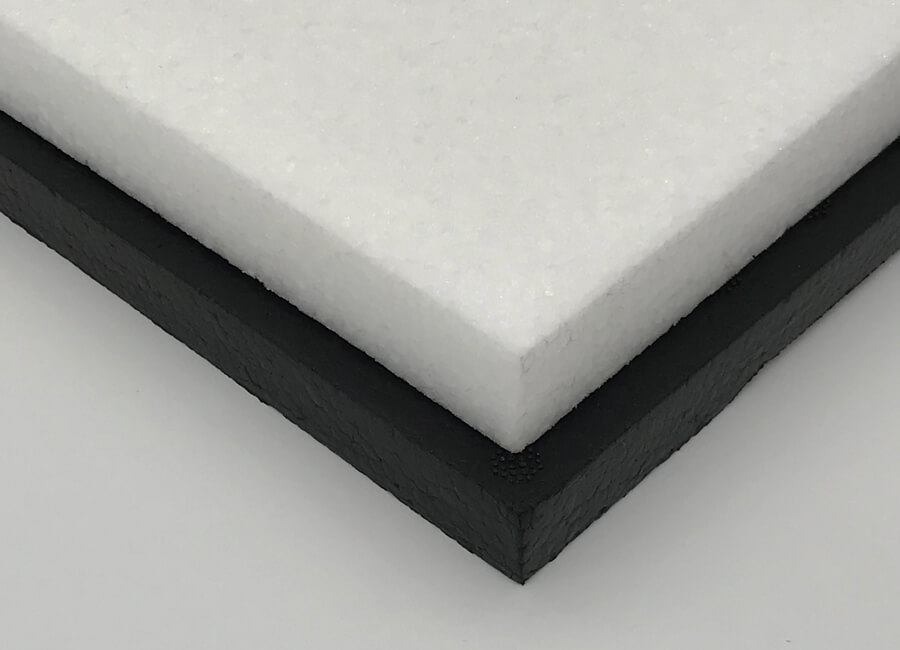

EPP is a popular material in the shipping industry, and it is meant to protect the contents of boxes and packages. In this application, it is often found in white. However, other colors are also common, particularly black, especially when it comes to industrial and automotive applications.

How is EPP (Expanded polypropylene) made?

EPP (Expanded polypropylene) is a remarkable material with many perks. It’s highly appreciated because of its light-weight, acoustic absorption properties, as well as thermal insulation, and sustainability. EPP is so widespread; it’s easy to forget that its manufacturing is a rather complex affair, requiring specialized tools and a lot of experience.

Facilities for the production of EPP are often outfitted with highly specialized instruments, measurement gear, and equipment, specifically designed for the purpose of EPP manufacturing and shaping. In fact, Expanded polypropylene can be shaped in many different formats, and it is also available in different colors, often depending on the specific industrial application.

EPP can be produced in great quantities, and it is usually considered more affordable than other materials with analogue properties, yet just as effective. EPP foam consists of polypropylene beads that are not packed together very densely. In fact, they allow some air space between the beats. This is great for acoustic insulation and thermal retention since they trap sound waves and air. In addition to that, the particular structure of the material also means that EPP is very light-weight. This is why it’s often used in the automotive industry when insulation is needed, without wanting to add extensive extra weight. EPP is also an excellent choice to protect items in boxes and packages, without adding too much additional weight.

Get to Know the Advantages of EPP Foam

EPP (Expanded polypropylene) is a multi-functional closed-cell bead foam that has a substantial number of uses and applications. It is lightweight, durable, and recyclable besides providing optimal energy management.

Some of the primary applications of EPP foam include:

- Industrial packaging

- Automotive parts

- Logistics and wrapping

- Shipbuilding

- Food preservation

- Waterproofing

- Lightweight constructions

- Furniture and design

- Suitable for a wide range of foam fabrication processes

The versatility of expanded polypropylene is the result of almost 50 years of research that has seen it become one of the most used products on the planet. Nowadays, EPP foam is heavily used in numerous manufacturing industries for its indisputable advantages, such as:

VIBRATION ABSORPTION

EPP foam comes in a broad range of densities that range from 15 to 200 grams per liter. Through molding, its density may increase to as much as 260 grams per liter. This impeccable density feature coupled with its high elasticity trait makes it ideal for insulating various environments against sound and vibration.

The polypropylene beads have a cylinder shape that allows for air to enter and remain in the space between them. As a result, even a thin layer of EPP foam provides reliable acoustical insulation. When used in thicker layers, this material becomes optimal for protecting rooms and vehicles from sounds and vibrations.

THERMAL INSULATION

EPP foam has a high thermal resistance that makes it perfect for insulation. This material is often used in the food industry to maintain foods and beverages in optimal conditions. Expanded polypropylene can keep most products at a stable temperature between that may range from -40 to +60 °С for a significant period.

Additionally, EPP foam prevents microbial growth and is often considered as a sterile medium for safe food packaging. By adding fire-retardant agents in its composition, EPP develops a low risk of flammability and high resistance to UV rays.

WATERPROOF AND BUOYANCY

One of the main advantages of EPP foam is its resistance to water. Even in conditions of high humidity, the material maintains its mechanical properties and ensures optimal water obstruction.

In addition, expanded polypropylene provides long-term buoyancy and as such, it is frequently used in the shipbuilding industry.

EPP foam cells are water-tight and almost impenetrable by other liquids and chemicals. This high-performance trait makes it an ideal material for waterproofing electrical appliances. It also recommends it for everyday use in isolating humidity-prone environments like bathrooms, saunas, and showers.

Since EPP foam is both waterproof and non-toxic, it is perfect for isolating potable water tanks, filters and other facilities where water quality standards need to be paramount.

UV AND OZONE RESISTANCE

Last, but not least, EPP foam has a high-resistance to UV rays. Its unique construction recommends it for outdoor insulation especially in areas that are heavily exposed to harsh weather and other environmental stresses.

Expanded polypropylene is suitable for geographical areas where the ozone layer is thin and where UV rays can affect entire communities of people. This safe and eco-friendly foam is perfect for protecting the environment against radiation, degradation, and abrasion.

Application of EPP (Expanded Polypropylene) Foam

One of the most versatile parts is EPP foam. These foam beads can be placed in molds, allowing them to form multiple shapes. Though you might not have heard of it, it can be used in a range of situations. Let’s look at some of the most common applications for this foam.

Automotive Industry

One of the most common places to use EPP is in the automotive industry. There are multiple reasons why EPP has become so widely used in this industry. For example, car manufacturers appreciate how durable and functional it is. For this reason, EPP can be found in multiple products. Some common examples might include; door panels, headrests, sun visors, bumpers, and seats. It can also be used to construct multiple other parts.

Packaging

Another popular way to use EPP is to make packaging. Distributors are always looking for ways to make sure that delicate items get to their customers safely. For this reason, they frequently choose to use EPP foam. There are multiple reasons why they do this. First, this foam is very lightweight. This means that it doesn’t cost much to ship. Also, it has high shock absorption. This ensures that it will provide adequate protection for items that are accidentally dropped. Finally, because they don’t need high-quality EPP for packaging, they can purchase this material cheaply.

Industrial Products

Increasingly, industries are looking for ways to offer high-quality prices at lower costs. They can do this by using EPP foam. This product is lightweight and can easily be cut into various shapes. It’s very durable, helping industrial products last for a long time and provide good value for money. They can also absorb the energy from an impact. For this reason, they can be used to create a safer work environment, providing protection if something goes wrong. Finally, products made with EPP are very strong. This means it can take a large strain before it breaks.

Consumer Goods

EPP is used to create a range of consumer products. There are a few simple reasons for this. First, it is lightweight. This ensures that products made from EPP will be easy to ship. Also, the foam can be easily molded into a wide range of shapes. Manufacturers can also color EPP, this makes it perfect for creating products like colorful children’s toys. Finally, EPP is anti-microbial. This makes it perfect for making products like food coolers, reducing the chances that people will get diseases from using the container. Because of these benefits, there are multiple consumer products that are made from EPP. Some common examples include; furniture, model aircraft, floor levelers and shelving units.

One of the most important substances is EPP foam. As we’ve seen, it can be found in a wide range of products across multiple industries. This is because of a range of unique qualities that this substance possesses. Hopefully, you now have a better understanding of what EPP foam is and how it might be used.

Leave A Comment